In Xcentric we have not invented the Crusher, in Xcentric we have simply perfected it

How to achieve maximum profitability with minimum maintenance

We have a network of distributors worldwide.

If you want more information or see any of our Crushers in operation, leave us your contact information and we will be happy to advise you.

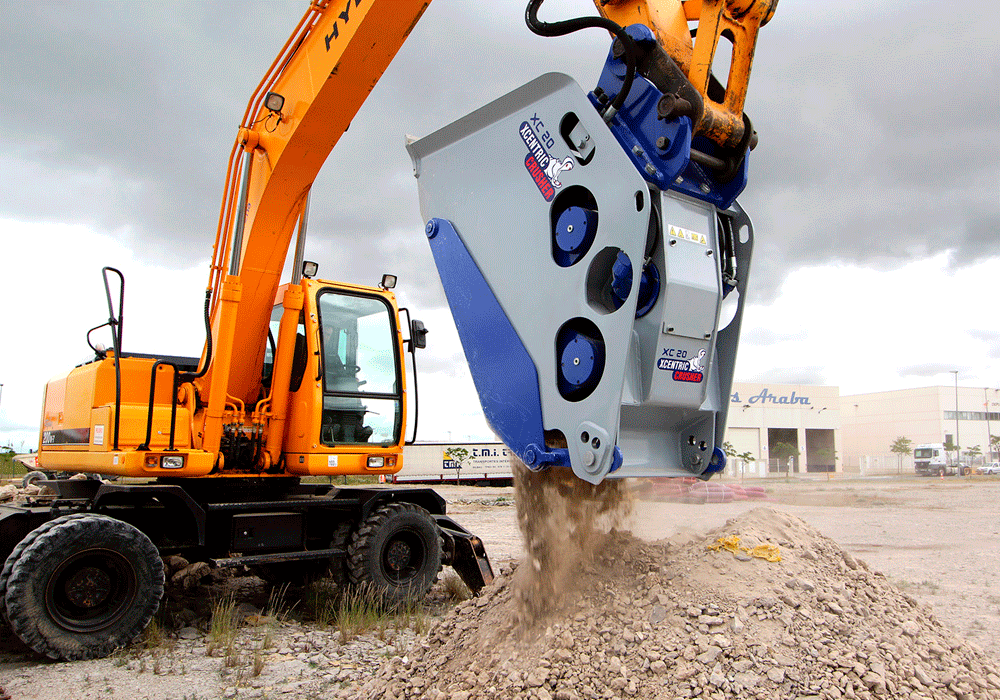

The Xcentric ® Crusher works with a circular jaw movement, achieved thanks to the 2 hydraulic motors which provide the Crusher with great power, also allows to start crushing at full load and in closed position. The full charge saves turns for loading, with the consequent increase in production.

This circular motion works in the direction of the material output, opening slightly at the end of the path facilitating the material falling, especially when it is wet.

In addition, its double effect hydraulic system allows operators to simply reverse the crushing movement in the event of a product jam without having to empty content, which again translates into higher production.

All of this with minimal maintenance (greasing every 50 hours) and 80% less fuel than a conventional shredder.

How is Xcentric Crusher different from traditional crushers?

- – High performance: in rock crushing and material recycling.

- – Higher profitability than mobile crushers.

- – Minimum maintenance: 50 hour greasing intervals.

- – 80% less consumables parts than conventional crusher buckets. No Toggles, No Springs, etc.

- – High inertia power train: 2 engines that give the necessary power to start full and in closed position.

- – Isolating jaw movement (PATENTED): ensures the material is crushed without compacting effect and giving greater production than conventional crusher buckets.

- – Anti-stagnation plate: innovative and simple (PATENTED). Continuously pushes the material preventing it from getting traversed or blocked, and directing it towards the outlet.

- – Simple and fast granulometry adjustment system: Allows adjustment of output size en less than 2 minutes , giving you an output product of 20mm to 210mm. (according to models)

- – Anti-skid Transmission: Higher production, less jams.

- – Wet material crushing: thanks to the Cross Top Jaws and its circular motion.

- – Double Effect: Double Effect Hydraulic System allows operators to simply reverse the crushing movement in the event of a product jam, without having to empty content.

- – Manufactured in Hardox 400: from the Swiss supplier SSAB. Maximum quality and resistance to wear (flexibility).

- – Cross top jaws: the movable jaw “bites” the wet material and along with the circular movement drags it towards the exit mouth.

About us

We are experts in the manufacture and international marketing of attachments for excavators. Our main products are the Xcentric Ripper hydraulic ripper, the Xcentric Crusher bucket and the Xcentric Screener bucket, as well as quick couplers and a wide range of buckets.

The complete manufacturing process involves a total Pool of 60 diverse state-of-the-art machines, to achieve quality parts in competitive times: machining centers, milling machines, boring machines, automatic threading machines, welding robots, folding machines, rollers, plasma and laser cutting machines, presses, lathes and cylinder grinders.

In this way we are able to achieve quality parts in competitive times. We have a stock of finished pieces, always available to be sent to the assembly area to quickly dispatch any arriving purchase order.

Where we are

Arriurdina Kalea, 15, 01015 Vitoria-Gasteiz, (España)

Copyright Xcentric Ripper – 2021 | PRIVACITY POLICY | COOKIES POLICY