"In Xcentric we have not invented the Crusher, in Xcentric we have simply perfected it"

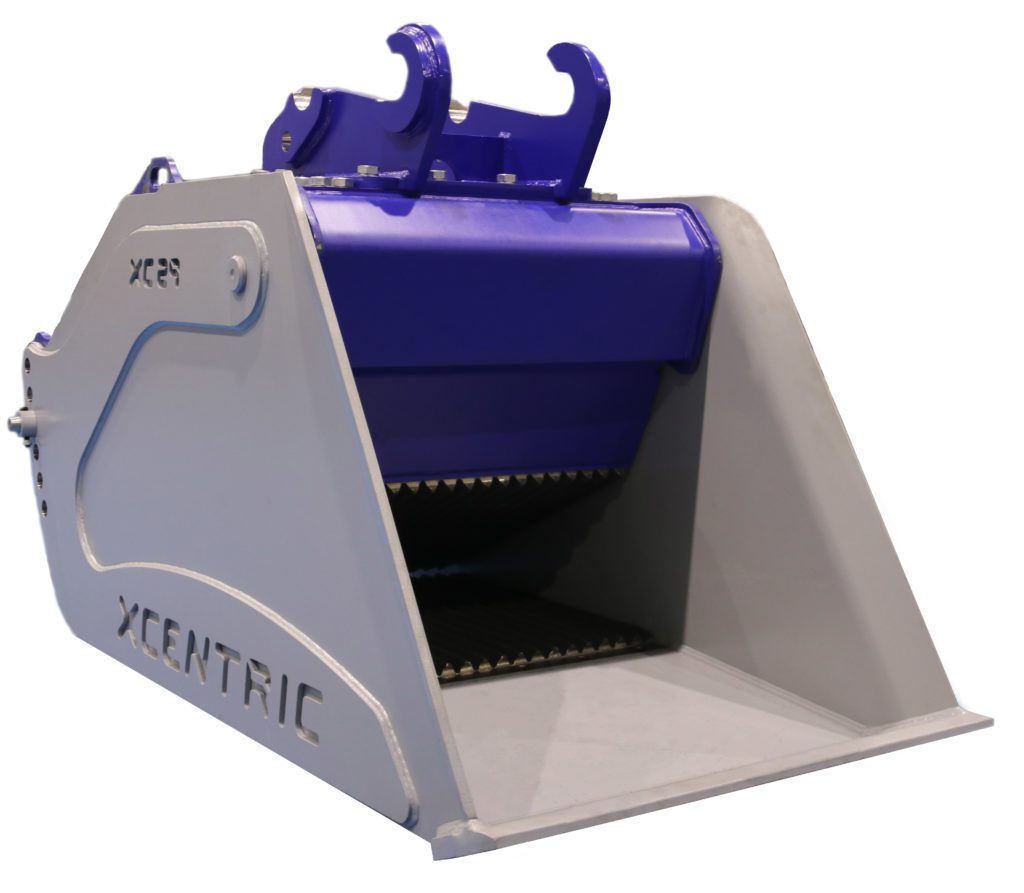

New A Series, much more than you expect from a crushing bucket

We have a network of distributors worldwide.

If you want more information or see any of our Crushers in operation, leave us your contact information and we will be happy to advise you.

The Xcentric Crusher Series A was born to exceed all expectations.

It has a totally redesigned powertrain. The integrated flywheel inside the bucket makes it possible to fully load the Crusher, put it in working position and start.

Its start recalls the sound of a steam locomotive, as if there was no way to stop it except for the stagnation of some metal part inside. But, as is common with our Crushers, the “Reverse” function will unblock the jaws without the need to empty the load.

It also has a new granulometry adjustment system that offers speed of change, together with a greater possibility of output sizes.

The flow control valve makes the equipment easily interchangeable between excavators, with very low risk of failure due to poor hydraulic adjustment.

Xcentric Crusher Differentiating Features - Class A

- – High versatility compared to a mobile crusher

- – Undeniably profitable production volumes

- – Unstoppable powertrain

- – Anti-stagnation plate

- – Quick and efficient grain size adjustment

- – Toothed belt drive

- – Made entirely of HARDOX 400

- – Unblocking function “REVERSE”

- – Clean design without fairings

About us

We are experts in the manufacture and international marketing of attachments for excavators. Our main products are the Xcentric Ripper hydraulic ripper, the Xcentric Crusher bucket and the Xcentric Screener bucket, as well as quick couplers and a wide range of buckets.

The complete manufacturing process involves a total Pool of 60 diverse state-of-the-art machines, to achieve quality parts in competitive times: machining centers, milling machines, boring machines, automatic threading machines, welding robots, folding machines, rollers, plasma and laser cutting machines, presses, lathes and cylinder grinders.

In this way we are able to achieve quality parts in competitive times. We have a stock of finished pieces, always available to be sent to the assembly area to quickly dispatch any arriving purchase order.

Where we are?

Arriurdina Kalea, 15, 01015 Vitoria-Gasteiz, (España)

Copyright Xcentric Ripper – 2021 | PRIVACITY POLICY | COOKIES POLICY