WHAT ADVANTAGES DOES WORKING WITH THE XCENTRIC CRUSHER BUCKET HAVE?

- High performance: in rock crushing and material recycling.

- Higher profitability than mobile crushers.

- Minimum maintenance: 50 hour greasing intervals.

- 80% less consumables parts than conventional crusher buckets. No Toggles, No Springs, etc.

- High inertia power train: 2 engines that give the necessary power to start full and in closed position.

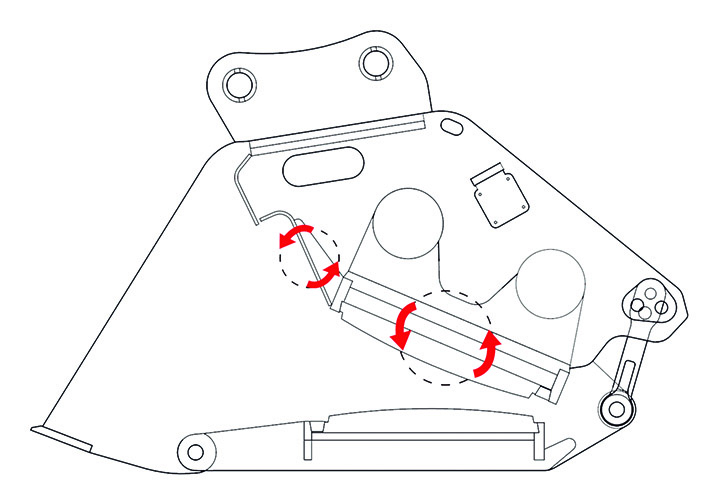

- Isolating jaw movement (PATENTED): ensures the material is crushed without compacting effect and giving greater production than conventional crusher buckets.

- Anti-stagnation plate: innovative and simple (PATENTED). Continuously pushes the material preventing it from getting traversed or blocked, and directing it towards the outlet.

- Simple and fast granulometry adjustment system: Allows adjustment of output size en less than 2 minutes , giving you an output product of 20mm to 210mm. (according to models)

- Anti-skid Transmission: Higher production, less jams.

- Wet material crushing: thanks to the Cross Top Jaws and its circular motion.

- Double Effect: Double Effect Hydraulic System allows operators to simply reverse the crushing movement in the event of a product jam, without having to empty content.

Design:

- Inertia wheels are placed inside and protected by the housing.

- Cantilevered loading mouth: it avoids wear and fracture, also favouring loading and protecting the sides of the attachment.

- Manufactured in Hardox 400: from the Swiss supplier SSAB. Maximum quality and resistance to wear (flexibility).

- Cross top jaws: the movable jaw “bites” the wet material and along with the circular movement drags it towards the exit mouth.

WHAT BENEFITS DOES THE XCENTRIC CRUSHER ‘A’ SERIES HAVE?

- New kinematics, new jaw movement, which achieves high production rates and has significantly reduced stagnation, requiring less power supplied by the excavator.

-

More precise and simple granulometry adjustment, and with a greater range of possibilities. It reduces the time the operator needs to adjust output sizes.

-

It does not generate waste.

- Redesigned power train, unstoppable.

-

It requires less power supplied by the excavator when working, so it consumes less and pollutes less.

-

The entire hydraulic system has been redesigned, protecting the machine against errors when installing in different excavators.

- The replacement of the jaws in case of wear is very easy, since the bucket can be opened completely to perform this operation.

- In some cases, depending on the material, sand can be obtained as the final result.

-

Made entirely of HARDOX 400.

-

Clean design without fairings.

-

The flow control valve makes the equipment easily interchangeable between excavators, with very low risk of failure due to poor hydraulic adjustment.

WHAT ADVANTAGES DOES THE XC5F MODEL HAVE?

- For small machines: skid steers, telehandlers and backhoes. -> Watch video

-

Unquestionably profitable production volumes.

-

New system of dumpers: very important acoustic reduction.

-

Direct drive of the hydraulic motor: reduces mechanisms.

-

Minimum and easy maintenance.

-

Input capacity for big material.

- Fast and efficient change of granulometry.

-

It supports crushing in 2 directions: “forward” and “reverse”.

-

Very careful structural design.

- Very fast and easy jaw replacement.